Heavy Duty Connector Overview

Overview

Heavy-duty connectors are primarily used for electrical or signal connections between different devices or functional units,

which provides great convenience for the installation and maintenance of complex control devices.

Heavy-duty connectors are widely used in construction machinery, textile machinery, packaging and printing machinery,

tobacco machinery, electric locomotives and petrochemical power. Electrical and signal connections are required.

Application. It has become an international standard electrical connection component.

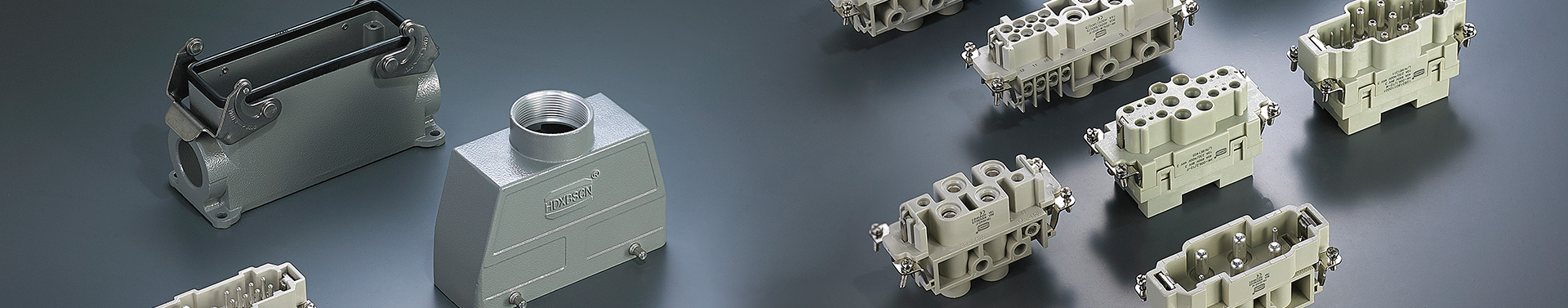

Connector

The basic structural components of the heavy-duty connector are: I. Connector II. Protective mounting housing III.

Connector attachment.

The connector is made of a VO grade material that meets UL94 VO and typically has a maximum operating temperature of 125.

However, after special treatment with PPS, it can withstand an external temperature of 180 degrees Celsius. The wiring methods

of the conductive terminals of different connectors are:

Screw crimping, cold press pin wiring, shrapnel crimping, roll pin wiring, axial bolt crimping, quick crimping, etc.

Mounting housing

The protective mounting shell is usually made of cast aluminum, and the surface of the shell is treated with powder coating or

self-extinguishing thermoplastic material (special series).

Make it resistant to impact or mechanical stress. The same seal between the housings allows the connector housing to be protected

to IP65 (EN60529).

The accessories include various cable connectors and different housing styles. A wide range of accessories offers a variety of different

solutions for different installation requirements.

Shrapnel crimping form,Roller needle wiring, axial bolt crimping, quick crimping, etc.

Customer settings

For the specific needs of customers, our company can also provide special development and fixed products, please contact us for details.

Specifications, standards and certifications

1. Product manufacturing specifications

VDE 0110 creepage distance and clearance

VDE 0627 plug and socket

2. Standard

DIN EN 175301-801

DIN EN 60664-1

DIN EN 61984