Re-recognizing the meaning and importance of heavy-duty connectors

In the industrial process of rapid development of informationization and electronicization, connectors play an increasingly important role because they can simplify the assembly process of production equipment, improve the flexibility of design and production, and improve the degree of the entire system. Whether it is "Made in China 2025", "Industry 4.0", or "Intelligent Manufacturing" and "Industrial Internet of Things" that we often mention, all that we hope to achieve is the connection of equipment and equipment, the connection of equipment and people, and people. The connection to the data, and all of this needs to rely on the connector to play a huge role.

Connector Requirements in the Industry 4.0 Era

Regardless of the small size of the connector, as industrial manufacturing is moving toward automation and intelligence, connectors that are widely used in equipment, factory automation, power distribution, and railways are constantly changing and innovating. In order to meet the domestic industrial transformation and upgrade and achieve the goal of Industry 4.0, the connector poses a new challenge, not only to have excellent performance, can be used in harsh industrial environments, but also to meet the diverse needs of users for intelligent control equipment. . Traditional connectors have been difficult to meet the needs of this market, when heavy-duty connectors were born.

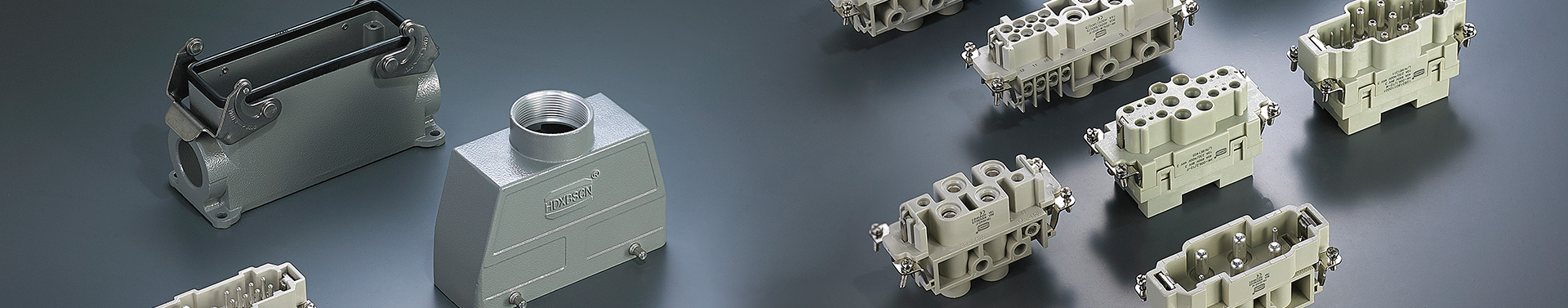

Heavy-duty connector, designed for demanding applications

Heavy-duty connectors designed to meet demanding applications. It mainly consists of three important components: ferrule, pin and outer casing. The ferrule and the pin form an electrical module that provides electrical connection to the device. The housing is made of metal or thermoplastic material and is structurally strong to provide reliable mechanical and environmental protection for electrical connections. The waterproof and anti-corrosion properties of the metal casing ensure that the heavy-duty connector can work in harsh environments and meet the needs of users for outdoor connections.

With a connector, don't use hardwired

When power, signal or data is transferred to a real application, there are usually two ways of wiring, permanent hard wiring or connector connections. When comparing these two options, you need to pay attention to a few points. The first and most important is the frequency at which the application will be disconnected/reconnected. When hard wiring is selected, each wire needs to be carefully removed and reconnected, which requires a lot of labor costs. If there are any wiring errors, it may take a few hours to troubleshoot.

The upfront cost of using connectors is high, but once completed, the plug-and-play solution avoids mis-insertion and does not require a dedicated technician. For many people, the long-term advantage of using connectors far exceeds hard wiring.

Heavy-duty connectors for diverse connection needs

The heavy-duty connector is modular in design and continuously expands functionality to the needs of the application. It not only realizes the barrier-free and fast connection between modular devices, but also ensures the transmission of signals and power supply, which satisfies the diversified connection requirements of users.

For mechanical equipment manufacturers, it saves installation time, safe and reliable connections, and reduces overall production costs. For the users of the terminal, they can install the operating equipment freely without the guidance of any professional, and the maintenance becomes simple. Its advantages are mainly reflected in the following three aspects:

Pre-installation of a large number of complex circuits is realized, which greatly improves the installation efficiency of the device and reduces the wiring error rate.

Provides highly integrated connectivity and a rich combination that maximizes the effective utilization of device space.

The modular structure of each functional template block of the device is conveniently and efficiently realized, so that the device can be transported, installed, maintained and repaired conveniently and safely.

Compared with traditional connections, the use of heavy-duty connectors can save 20-30% of the installation cost of the machining center, while increasing production efficiency, mainly used in industrial automation, equipment manufacturing and industrial systems buildings and information and control technology And other fields.